PROJECT STORY

The path to carbon neutrality connecting to the next generation:

The TSUNEISHI Group decarbonization roadmap

As the world shifts to decarbonisation, the TSUNEISHI Group, which is engaged in diverse businesses, is currently making additional breakthroughs. We are laying the groundwork for these breakthroughs by reducing CO₂ emissions, and it is imperative that we start by focusing on the shipbuilding, shipping, and environment businesses that have a relatively higher volume of emissions among our Group companies. Ships, in particular, represent our core products and serve as an essential infrastructure for everyday life. However, they also consume considerable fossil fuels over the long term, from building through scrapping. Our shipowner and shipper care deeply about our approach to this issue.

The TSUNEISHI Group is committed to aligning with our clients’ expectations. We will continue to be the company of choice by maintaining an awareness of our role and conscientiously addressing the development of a decarbonised society in a conscientious manner.

Learnings and organisational development to promote decarbonisation

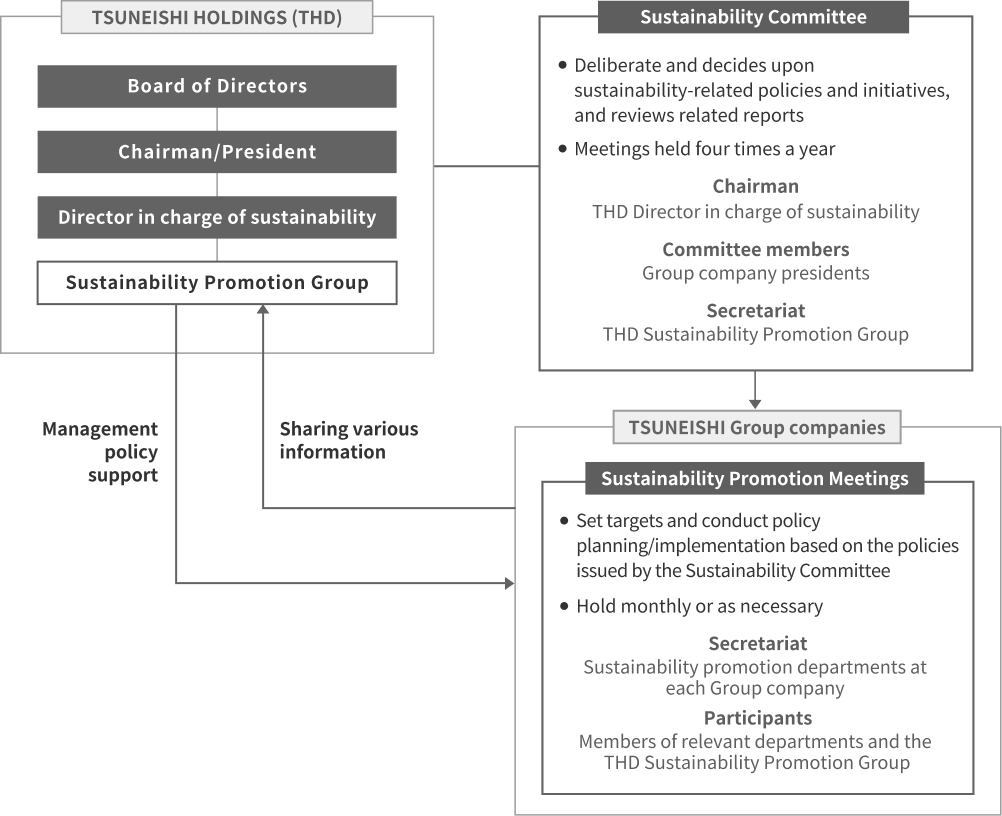

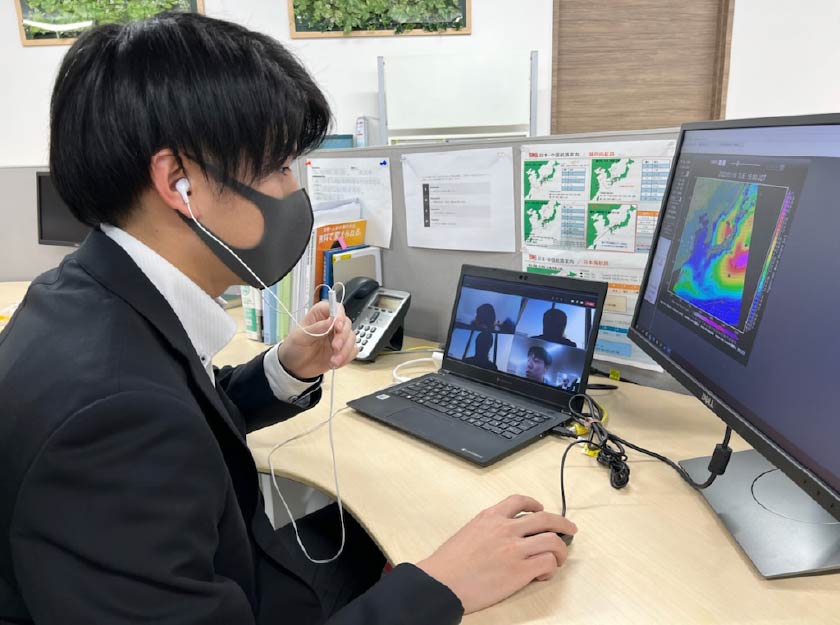

At the end of 2020, the government of Japan issued a Carbon Neutrality Declaration. In the following year, the TSUNEISHI Group established immediately an internal study group to gain a deeper understanding of the importance of decarbonisation. In 2022, we established the Sustainability Promotion Group in TSUNEISHI HOLDINGS, which then launched full-scale initiatives that inclusively engage all Group companies.

To promote sustainability initiatives, the Group has established a Sustainability Committee. The committee is chaired by the director in charge of sustainability at TSUNEISHI HOLDINGS, and its membership consists of the presidents of each operating company. It makes policy decisions, reviews each relevant initiative, and promotes activities across the entire Group.

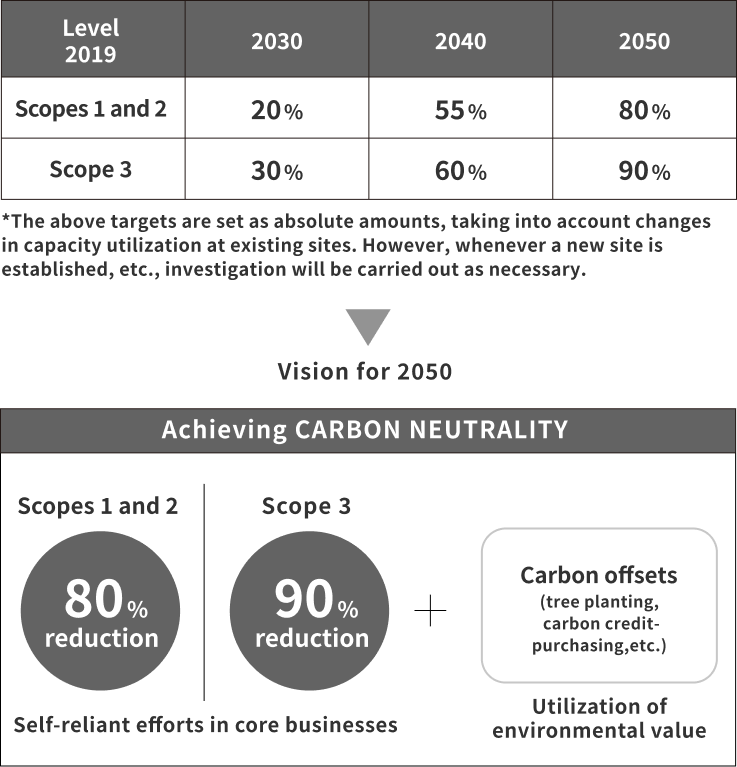

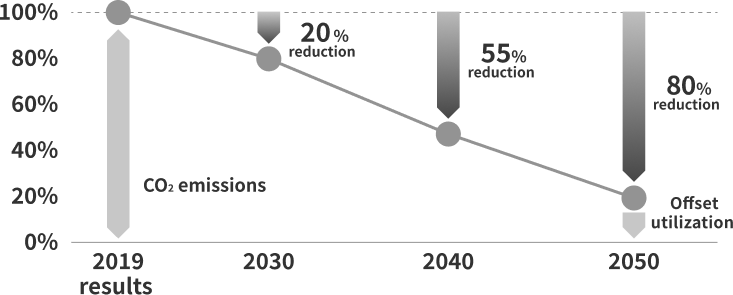

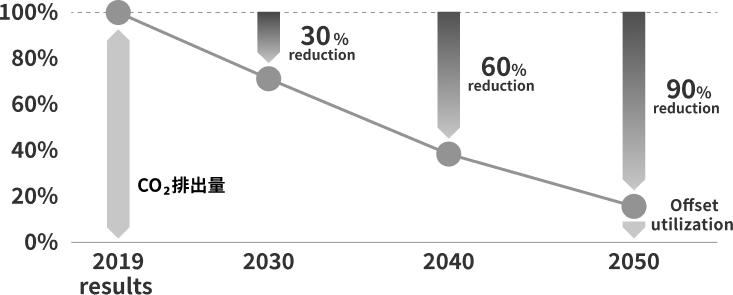

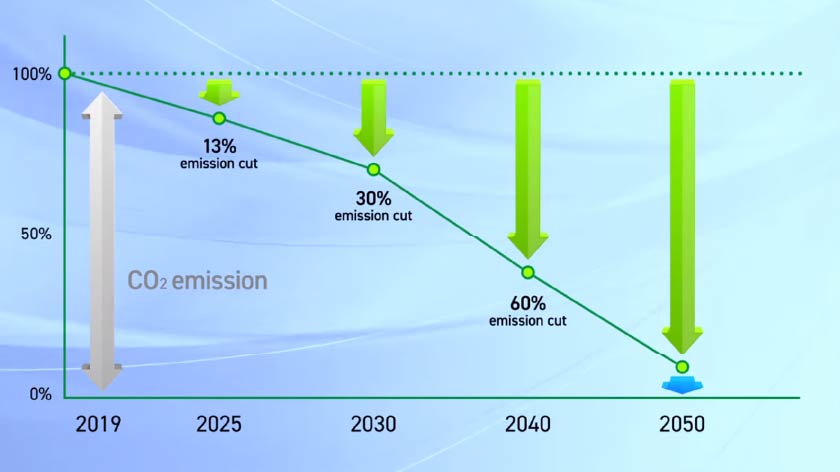

The TSUNEISHI Group CO₂ emissions decarbonization roadmap

The TSUNEISHI Group is establishing long-term CO₂ emissions reduction targets to be achieved by 2050 and will work to achieve milestone targets in 2030 and 2040 based on 2019 emissions levels.

As the crucial initial step in reducing emissions is to visualise the CO₂ emissions of each company. The TSUNEISHI Group has obtained third-party certification for calculated emissions. As the first dedicated shipbuilder to achieve this certification, we have improved the transparency of the Group’s current emissions, which helps to develop a foundation for highly focused, reliable initiatives.

A third-party organisation with expertise evaluates the sustainability initiatives of companies and organisations. A third-party certification is granted when international standards are met, thereby recognizing the reliability of the information. This certification is of significant benefit to business growth. Its presence or absence not only promotes internal decarbonization activities, but also serves as an evaluation point for external stakeholders and rating agencies in the future.

Examples of initiatives by the Group

Each company has set stringent standards based on its emissions. This section outlines in three segments (shipbuilding, shipping, and the environment) that can make a significant contribution to decarbonisation.

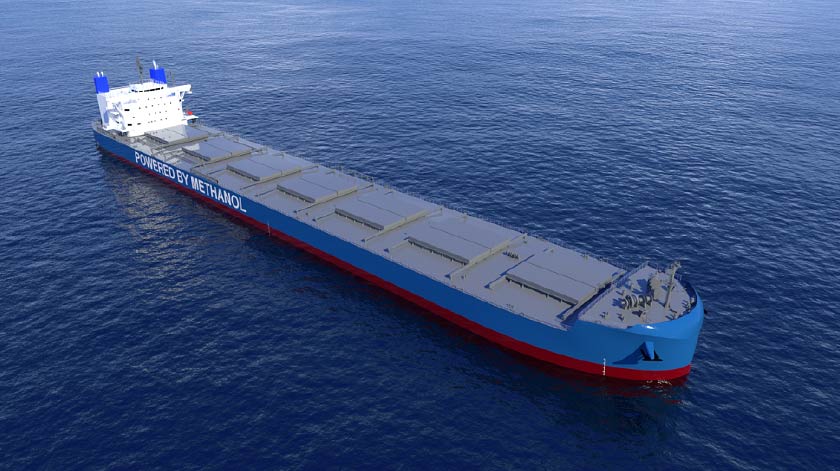

<Shipbuilding> Increasing orders for methanol dual-fuel ships

In January 2023, TSUNEISHI SHIPBUILDING became the first shipyard in Japan to develop and market a methanol dual-fuel ship. In addition to operating on fuel with a low environmental impact, fuel efficiency has been significantly improved compared with conventional ship models. The ship has attracted significant interest from the shipping and shipbuilding industries due to its combination of environmental performance and economy. To date, we have received orders for approximately 30 ships.

Research and development of energy-saving technologies

We will continue to refine our technology and expertise in improving fuel efficiency, and develop technologies to ensure customer satisfaction.

An energy-saving device features fins mounted in front of the propeller, which recover energy losses due to propeller rotational flow.

An originally-designed propeller optimised for TSUNEISHI SHIPBUILDING ship models that improves fuel consumption and noise reduction effects.

An air intake system that directly intakes air from outside the ship to improve engine combustion efficiency.

Introduction to shipbuilding initiatives

<Shipping> Aiming for operations that are both efficient and the optimum environmental solution

For the ocean voyage shipping business, we adhere to schedules and have implemented fuel-efficient operations to minimize our environmental impact. Similarly, our coastal tugboat business also operates in an environmentally-friendly manner, with high fuel efficiency.

■Logistics services directly linking to local ports in Japan

The transportation of international cargo through domestic key ports has a significant impact on the environment, particularly in the context of land transportation process. Furthermore, it is becoming increasingly difficult to recruit and retain transport vehicle drivers. Services that directly link key Chinese ports and local Japanese harbours streamline the supply chains of clients with regional production/logistics bases, while also providing an effective approach to resolving global warming issues.

Operation services and implementation of environmentally-friendly state-of-the-art ships

We operate 1,000+TEU-types, which are the optimal ship models for entering most of Japan’s mainland local ports. With regard to owned ships, KAMBARA KISEN will collaborate with the Group company TSUNEISHI SHIPBUILDING Co., Ltd. and will adopt, at an appropriate time, cutting-edge ships that incorporate environmental emission regulations ahead of time, in order to reduce the environmental impact. Furthermore, a ship operation control working team has been established in Shanghai, with ship information integrated at the HQ for cross-border operation management of our ships. We have our own bases for container sales in Japan (three locations) and China (seven locations), as well as a large number of local partners in Japan and abroad. This enables us to provide global support to customers regardless of their location.

<Environment> Recycling waste with the aim of zero landfill disposal

We promote diverse stabilization and detoxification treatments for waste as well as active recycling with the target of zero landfill at final disposal sites. We will create new value for waste under our vision: “become essential to achieving a sustainable society.”

Building a recycling society

We engage in developing and selling recycled products that utilise waste as a raw material.

From here, we will step up research and development of new recycling technologies for solar power panels, batteries, and other items, with the aim of building a recycling society.

Cultivated recycling technologies

Molten slag (product name: Melissa)

This is used in civil engineering and construction material.